General principles

Modeling

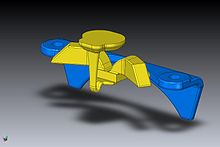

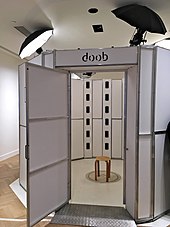

3D printable models may be created with a computer-aided design (CAD) package, via a 3D scanner, or by a plain digital camera and photogrammetry software. 3D printed models created with CAD result in relatively fewer errors than other methods. Errors in 3D printable models can be identified and corrected before printing.[48] The manual modeling process of preparing geometric data for 3D computer graphics is similar to plastic arts such as sculpting. 3D scanning is a process of collecting digital data on the shape and appearance of a real object, creating a digital model based on it.

CAD models can be saved in the stereolithography file format (STL), a de facto CAD file format for additive manufacturing that stores data based on triangulations of the surface of CAD models. STL is not tailored for additive manufacturing because it generates large file sizes of topology optimized parts and lattice structures due to the large number of surfaces involved. A newer CAD file format, the Additive Manufacturing File format (AMF) was introduced in 2011 to solve this problem. It stores information using curved triangulations.[49]

Printing

Before printing a 3D model from an STL file, it must first be examined for errors. Most CAD applications produce errors in output STL files,[50][51] of the following types:

No comments:

Post a Comment